| 產(chǎn)品類型 | 全新 |

|---|---|

| 動力類型 | 電動 |

| 控制形式 | 數(shù)控 |

| 類型 | 銑齒機(jī) |

| 重量 | 315kg |

| 主電機(jī)功率 | 7.5kw |

| 是否庫存 | 否 |

| 布局形式 | 臥式 |

| 作用對象材質(zhì) | 金屬 |

| 品牌 | 興源 |

| 型號 | xy |

| 最大加工模數(shù) | 3 |

| 加工直徑范圍 | 10-100 |

| 加工精度等級 | 11.0 |

| 加工齒輪類型 | 直齒,弧齒,斜齒 |

| 最大加工齒數(shù) | 100 |

目 錄

一、 機(jī)床用途

二、 適用范圍

三、 倒角效果及效率

四、 機(jī)床坐標(biāo)軸

五、 技術(shù)參數(shù)

六、 操作流程

七、 倒角大小調(diào)整原理

八、 倒角進(jìn)給運動控制原理及其實現(xiàn)

九、 機(jī)床配置

十、 電氣配置

十一、 進(jìn)給系統(tǒng)

十二、 刀具選擇

一、 機(jī)床用途

1、內(nèi)/外齒復(fù)合倒角

2、倒角大小任意調(diào)節(jié)

3、倒角尺寸一致

4、效率高

二、適用范圍

本產(chǎn)品可廣泛應(yīng)用于各類中、大規(guī)格的內(nèi)/外齒圈全自動倒角。

三、 倒角效果及效率

加工效率:

效率計算公式0.7mz,單位S,其中m為工件模數(shù),z為工件齒數(shù)。

驅(qū)動滾輪線速度不低于3.14*0.5*190/1000=0.298m/min倒角不均勻度小于0.2mm。

| 軸名稱 | 軸標(biāo)識 |

| 主立柱進(jìn)給 | X |

| 從動滾輪座進(jìn)給 | X1X2 |

| 刀具前后移動進(jìn)給 | X3X4 |

| 上下刀架進(jìn)給 | Z1Z2 |

| 夾緊電機(jī)進(jìn)給 | U |

| 龍門架進(jìn)給 | W |

| 油缸上下進(jìn)給 | W |

| 主軸刀具旋轉(zhuǎn) | SP1SP2 |

| 驅(qū)動滾輪旋轉(zhuǎn) | SP3SP4 |

|

|

|

五、 技術(shù)參數(shù)

| 參數(shù)項目 | 單位 | 參數(shù)指標(biāo) |

| 齒輪類型 |

| 內(nèi)/外直齒圓柱齒圈 |

| 工件直徑 | mm | 1500-5000 |

| 工件寬度 | mm | 150 |

| 倒角 | mm | 小于3×45°(倒角度數(shù)也可由刀具調(diào)整) |

| 上下驅(qū)動輪轉(zhuǎn)速 | rpm | 1-1.5 |

| 工作臺承重 | Kg | 5000 |

| 設(shè)備總功率 | kw | ≤10 |

| 電源 | V/Hz | AC380±10% 50Hz |

| 液壓壓力 | Mpa | 6 |

| 氣源壓力 | Mpa | 0.4~0.7 |

| 設(shè)備重量 | Kg | 6000 |

◆機(jī)床利用仿形測頭按齒面形狀在極坐標(biāo)內(nèi)實現(xiàn)仿形銑削加工;

◆利用刀架垂直進(jìn)給伺服系統(tǒng)將上下刀架垂直滑臺(帶有主軸)處于正確

位置;

◆根據(jù)倒角設(shè)置值大小調(diào)整兩刀架垂直滑臺位置,滿足倒角要求;

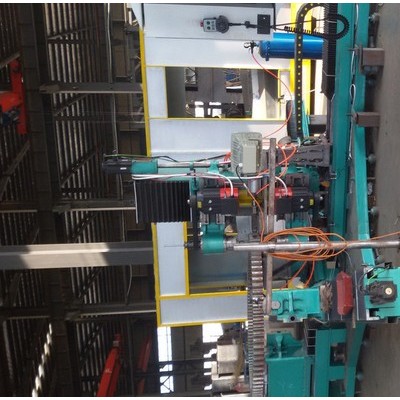

八、倒角進(jìn)給運動控制原理及其實現(xiàn)

——機(jī)床利用仿形測頭按齒面形狀實現(xiàn)仿形銑削加工。

——刀架底座滑臺沿徑向后退,保證仿形頭可靠地抵在齒面上,并使得兩刀架

水平進(jìn)給滑臺的配重(或氣缸)處于合適的張緊位置;

——工件在上、下驅(qū)動輪的驅(qū)動下實現(xiàn)周向旋轉(zhuǎn),仿形測頭在氣缸作用下實現(xiàn)

徑向進(jìn)給。銑削刀具在電主軸的驅(qū)動下高速旋轉(zhuǎn),并通過調(diào)節(jié)結(jié)構(gòu)和仿形

頭之間處于合適的位置,當(dāng)仿形頭抵在齒面上,銑刀恰好處于倒角工作位

置,實現(xiàn)倒角切削;

——當(dāng)工件旋轉(zhuǎn)一周后,完成一個齒圈的上、下面同時倒角。

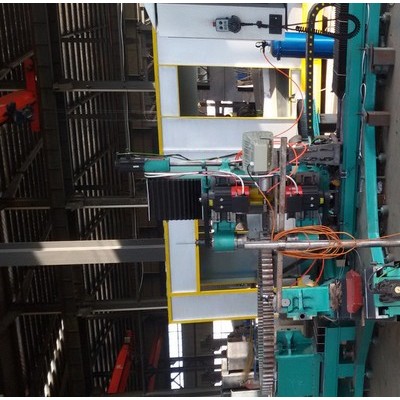

九、機(jī)床配置

1、 采用歐姆龍觸摸屏開發(fā)的人機(jī)界面,具有良好的人機(jī)接口和容錯性。

2、 用戶只需輸入齒數(shù)、模數(shù)、齒寬和倒角大小等主要參數(shù)。

3、 系統(tǒng)程序自動計算機(jī)床的初始化調(diào)整位置并進(jìn)行相應(yīng)的調(diào)整。

4、 控制系統(tǒng)將按設(shè)定的工藝流程實現(xiàn)倒角過程全自動化。

操作流程:

機(jī)床調(diào)整——手動回參考點——用戶程序——輸入工件信息——手動夾持工件——附件自動開啟——自動倒棱

十、電氣配置

電氣系統(tǒng)整體控制方案采用“觸摸屏+PLC+伺服驅(qū)動”模式。

歐姆龍 TP1200觸摸屏

歐姆龍 PLC控制器

日本伺服和電機(jī)

通過觸摸屏人際界面的開發(fā),能實現(xiàn)工作參數(shù)的輸入修改等功能。

只需要簡單的上下料輔助工作,機(jī)床便可完成工件倒棱的自動化過程。

十一、進(jìn)給系統(tǒng)

機(jī)床進(jìn)給運動采用滑臺結(jié)構(gòu)形式實現(xiàn),滑臺均采用線軌和滾珠絲杠進(jìn)行進(jìn)給驅(qū)動。

十二、刀具選擇

銑刀前端夾角大小和倒角在小匹配。

聯(lián)系人:高經(jīng)理

電話:0536-2621188

網(wǎng)址:www.xingyuankeji.com

地址:山東省高密市南外環(huán)路 SKDL-1600

雙銑頭齒輪棱機(jī)